Savvy is your trustable OEM manufacturer for custom o-rings and molded rubber o-ring seals.

- Payment Way: T/T, Western Union, Paypal

- Incoterm: EXW, FOB, CIF

- Shipping Way: By Air or Sea

- Manufacturer Place: Ningbo, China

- Delivery Time: 7 - 30 days

- Factory Status: Stocked for Sale

Share to SNS:

Description

Most mechanical designers will primarily use standard o-rings when designing products, but when they cannot find available o-rings in standard o-ring sizes, they need to choose custom o-rings. Savvy has been in the OEM o-ring industry for many years and can design and produce custom rubber o-ring seals in various cross-sections and shapes.

Types of Custom O-Rings

Custom o-rings are mainly defined in terms of cross-section and outline shape.

1. If the cross-section is outside the range of the standard o-rings below, it is a custom o-ring.

| Country | Standard | Cross Section (mm) | ||||

|---|---|---|---|---|---|---|

| USA | AS568 | 1.78 | 2.62 | 3.53 | 5.33 | 6.99 |

| UK | BS1516 | |||||

| Universal | ISO 3601 | 1.8 | 2.65 | 3.55 | 5.3 | 7 |

| China | GB/T 3452.1 | |||||

| Germany | DIN 3771 | |||||

| France | NFT47 501 | |||||

| Sweden | SMS l586 | 1.6 | 2.4 | 3 | 5.7 | 8.4 |

| Japan | JIS B 2401 | 1.9 | 2 | 2.4 | 3.1 | 3.5 |

| 4 | 5.7 | 6 | 8.4 | 10 | ||

| Preferred Metric Sizes | 1 | 1.5 | 2 | 2.5 | 3 | |

| 3.5 | 4 | 4.5 | 5 | 5.5 | ||

| 6 | 7 | 8.0 | 10 | 12 | ||

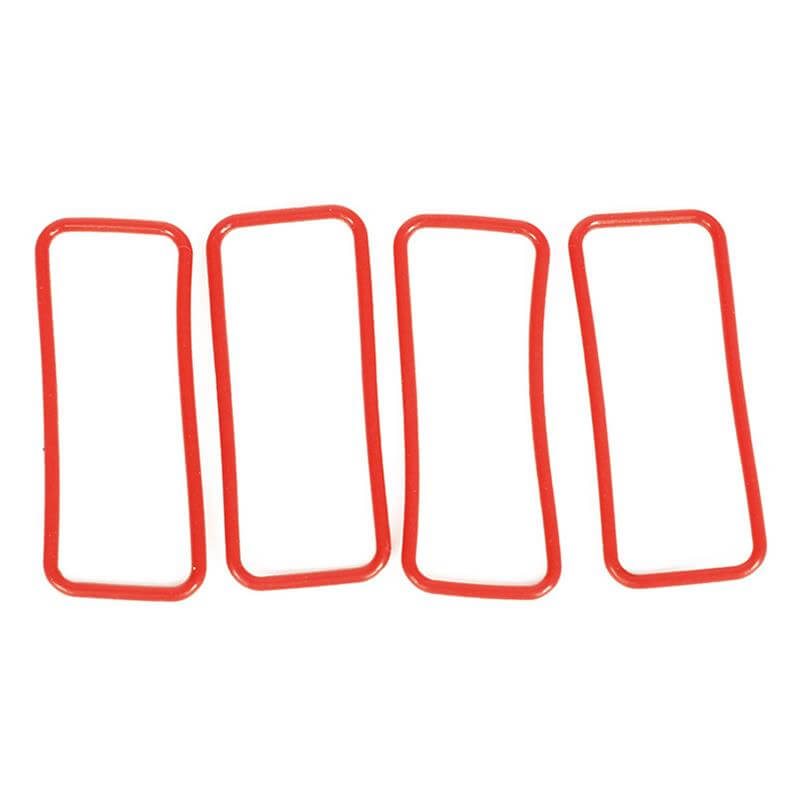

2. Even if the cross-section is within the range of the above standard o-rings, its outline shape is not round, but square, rectangular, or other irregular shapes, they are also called custom o-rings.

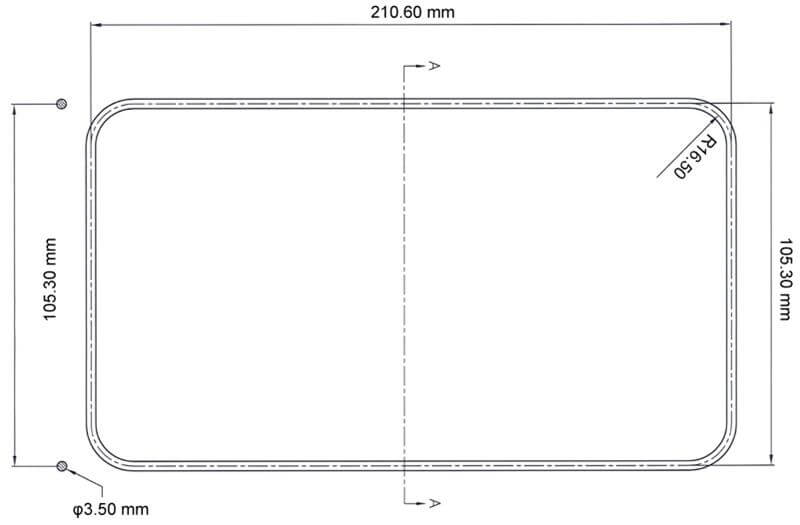

For the first custom o-ring, we only need to know its inner diameter (ID) and cross-section (CS), and then we can make a mold for production. For the second case, usually, the designer needs to design a drawing, and then send the drawing to us, so that we can make the mold and produce the products according to your drawing. If the customer cannot provide a drawing, we can also design it. Of course, this requires a lot of communication and close cooperation between the two parties to finally complete a perfect customized o-ring.

Due to the unconventional nature of custom o-rings, they are used in much less volume than standard o-rings, so their price is higher. Since Savvy has a strong cost control management, our price is always at a very low level in the China market while keeping the high quality.

Material, Hardness and Color

Application of Custom O-Rings

Although custom o-rings are used less frequently than standard o-rings, they are still popular in a wide variety of modern industries. These versatile rubber seals are commonly used in the following industries:

- Hydraulics & Pneumatic

- Oil and Gas

- Semiconductor Processing

- Aerospace

- Food Processing

- Water Filtration

- Electronic Products

- Machinery Fabrications

- Plastic Sealing

- Automotive

- Medical Equipment

However, to reduce procurement costs and lead times, we recommend considering standard o-rings first.