Leading High-Quality Rubber O-Rings Manufacturer & Supplier in China.

Savvy has more than thousands of molds in our factory and can meet your different sizes and shapes of o-ring order needs. We stock many o-rings and can arrange delivery instantly by door-to-door courier. Our courier company grants us the most favorable discount, so you only afford the lowest express cost.

O-Ring Products

Except for the traditional standard o-rings, we also manufacture encapsulated o-rings, backup-rings, x-rings, etc. At the same time, since we are a factory, we can make a custom o-ring at a very low mold/tooling cost and fulfill a fast delivery for our customers.

O-Ring Overview

O-Ring is a kind of rubber sealing ring with a circular cross-section to seal various fluids such as air, water, and oil. Because its cross-section is o-shaped, it is called o shape rubber seal, also called o-Ring. It is the most widely used element in hydraulic and pneumatic transmission systems. It is mainly used for mechanical parts to prevent the leakage of liquid and gaseous media under static conditions. In some cases, o-rings can also be used as axial dynamic sealing of reciprocating motion and low-speed rotating motion.

For different types of fixed sealing or dynamic sealing applications, o-ring seals provide designers with an effective and economical sealing element. As a two-way sealing element, the o-ring is installed in the medium groove, and the initial compression in the radial or axial direction during installation gives the o-ring its own initial sealing ability. The sealing force produced by the system pressure and the initial sealing force is combined into the total sealing force, which increases with the increase of the system pressure.

O-Ring Materials

O-rings can be made of rubber, metal, and other materials, but rubber is the most used material for o-rings. Savvy can produce popular rubber compounds, as well as some special compounds. According to different working conditions, different materials need to be selected carefully to achieve the best sealing purpose. The most commonly used o-ring materials are NBR, FKM, and Silicone.

NBR is the first considering material we suggest. About 50% of o-rings in the world are made of NBR compound because of its good property and low cost.

FKM / Viton is an o-ring material with the best comprehensive performance and is widely used in various sealing equipment with high standards. It was first invented by DuPont company and issued under the trade name “Viton”. With the time being, more and more people used to call this material Viton.

Silicone is more and more used in medical and food industries, especially FDA silicone. It is tasteless and non-toxic, not afraid of high temperatures, and resistant to severe cold.

Excepting the above popular rubber materials, other materials like EPDM, HNBR, CR, Aflas, etc. are also used in different equipment.

We manufacture the following main rubber material O-Rings with high quality and low price.

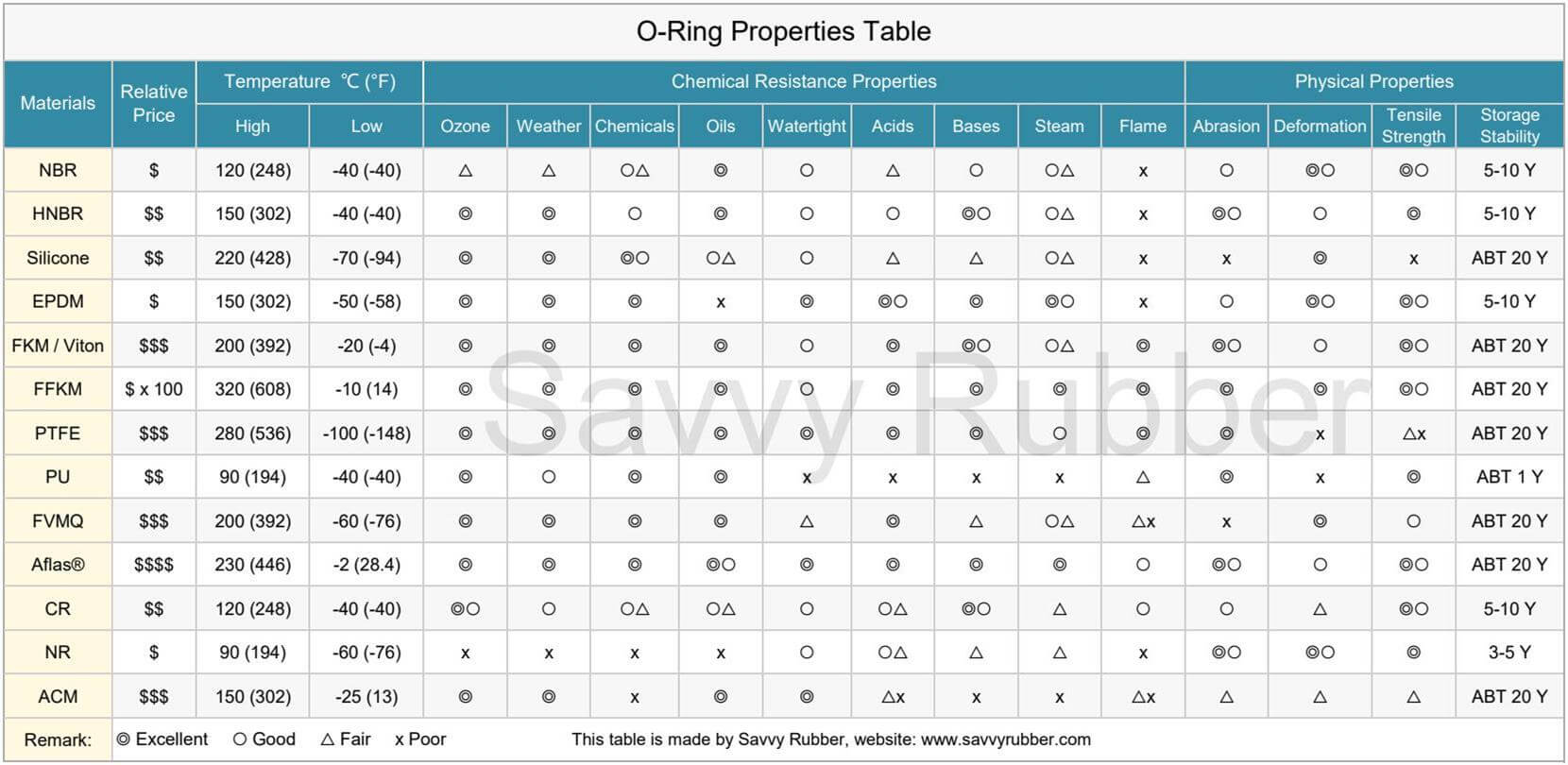

O-Ring Properties Table

Different elastomers have different compatibility with various chemical elements, as well as their own characteristics. See the table below for more material knowledge so you can order the most cost-effective o-rings from us.

O-Ring Sizes

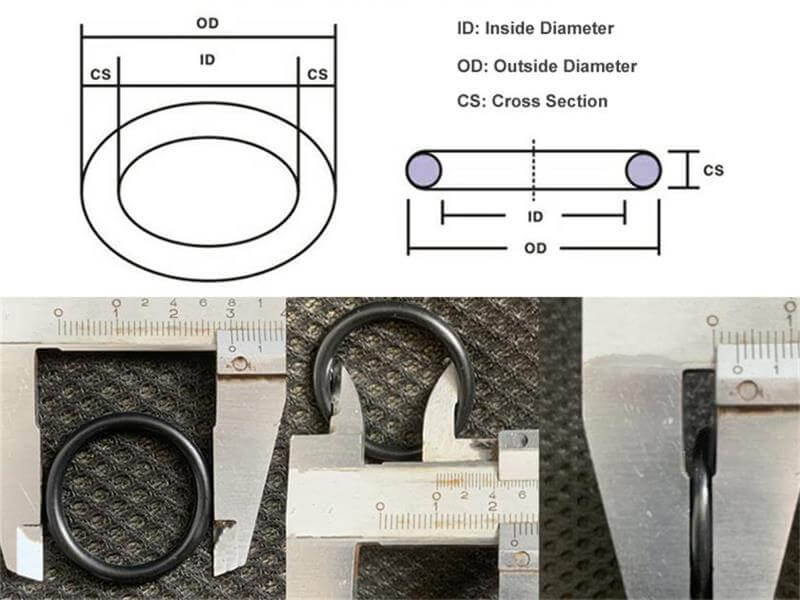

An o-ring has three sizes, ID (inside diameter), OD (outside diameter) and CS / W (cross-section / width). Normally to specify the ID and CS is enough, namely, a standard o-ring size will be given, ID 20 x CS 2 mm. From the right picture, you can easily know the

Outside Diameter = Inside Diameter + Cross Section * 2

OD = ID + CS*2

In history, different countries form their own standard o-ring sizes, like AS568 for the USA, BS1516 for the UK, DIN 3771 for Germany, JIS B 2401 for Japan, ISO 3601 for International, and GB 3452.1 for China.

O-Ring Hardness

The hardness unit of the o-ring is Shore A, which can be easily measured by a Shore A scale durometer. Generally, the hardness of o-rings is Shore A 40~90, but in use, Shore A 70 is generally more suitable, with the exception of silicone rubber whose Shore A 60 is generally used. The choice of o-ring hardness is more important. If the hardness is low, it is easy to install, but prone to peeling, installation damage, extrusion, and even pressure explosion. If the hardness is too high, the installation is inconvenient. Generally, 60~70 is low hardness, 80 is medium hardness, and 88 (or 90) is high hardness. When the sealing pressure is in the range of 30~60map, the hardness of the o-ring seal should be 85~90.

O-Ring Colors

O-Ring Features

O-rings are widely used in various dynamic and static sealing occasions because of their low manufacturing cost and convenient use.

Its advantages include: simple structure, small size, compact installation; self-sealing effect, no need for periodic adjustment; static seal can achieve zero leakage; strong adaptability, wide application; low price.

Its disadvantages include: when it is used for compression sealing, the starting friction resistance is large; if it is used improperly, it is easy to cause accidents such as cutting, twisting, and breaking; it is difficult to achieve zero leakage of dynamic seals, and it can only control its leakage amount is not greater than the specified allowable value; in some occasions, it is often necessary to install a protective backup ring and a dust ring, and sometimes it is necessary to equip various lubricating accessories in the air pressure and water pressure seals.