Leading High-Quality Oil Seals Manufacturer & Supplier in China

Savvy has more than 5,000 molds in our factory and can meet your different sizes of oil seal order needs. We stock some standard oil seals and can arrange delivery instantly by door-to-door courier or sea. Our courier company grants us the most favorable discount, so you only afford the lowest express cost. Meanwhile, you can also choose the ocean shipment for big orders.

Oil Seals Overview

Oil Seal is also called shaft seal that is widely used to prevent the leakage of medium (such as oils and grease) along a rotating shaft. It is a mechanical component used to seal grease (oil is the most common liquid substance in the transmission system, and also refers to general liquid substances). It isolates the parts that need to be lubricated in the transmission parts from the output parts so that the lubricating oil will not leak.

The representative oil seal is the TC oil seal, which is a double-lip oil seal with a self-tightening spring that is completely covered by rubber. Generally speaking, the oil seal often refers to this TC skeleton oil seal.

Oil Seal Products

Oil Seal Materials

Common materials for oil seals are NBR/Buna-N/nitrile, FKM/Viton, silicone, polyurethane, PTFE/Teflon, ACM, etc. NBR and Viton rubber materials are widely used on oil seals.

Nitrile rubber (NBR) – It has a good heat resistance and wear resistance, and is resistant to various lubricating oils, greases, oil and gas mixtures, etc., and is suitable for temperatures ranging from -30 to 120 degrees Celsius, but it cannot be used in phosphate ester hydraulic oils and gear oils containing extreme pressure additives. It is stable in gasoline and low aniline point mineral oil.

FKM/Vion – Aging resistance, heat resistance, oil resistance, suitable for almost all lubricating oil, fuel oil, gasoline, not easy to harden in oil containing extreme pressure additives, but poor cold resistance, high temperature wear resistance, large permanent compression deformation, suitable for At temperature -20~250 degrees Celsius.

Silicone ‘- It has outstanding high and low-temperature resistance, and can be used for a long time at 150 degrees Celsius without performance changes; it can be used continuously for 10,000 hours at 200 degrees Celsius and can maintain its unique use elasticity and ozone resistance and resistance in the working temperature range of -70~260 degrees Celsius. weather and other advantages.

PTFE/Teflon – It has outstanding chemical stability, thermal stability, friction reduction, and self-lubrication, and its cracking temperature is above 400. Therefore, it can work normally in the temperature range of -200~300 degrees Celsius. In addition to free fluorine and alkali metals, it has excellent corrosion resistance to chemicals, solvents, hydroxide compounds, and acids.

Polyacrylate Rubber (ACM) – Excellent oil resistance, heat resistance, wear resistance, ozone resistance, UV radiation resistance, especially resistance to extreme pressure fluids containing lubricating oil, gear oil, motor oil, motor oil, petroleum hydraulic oil, etc., suitable for -30~150 degrees Celsius scope work.

Oil Seal Types

There are many types of oil seals, like TC, TB, TA, SC, SB, SA, KC, KB, KA, VC, VB, VA, etc. We mainly manufacture the commonly used TC skeleton oil seals. The following picture is for your option reference.

Oil Seal Sizes

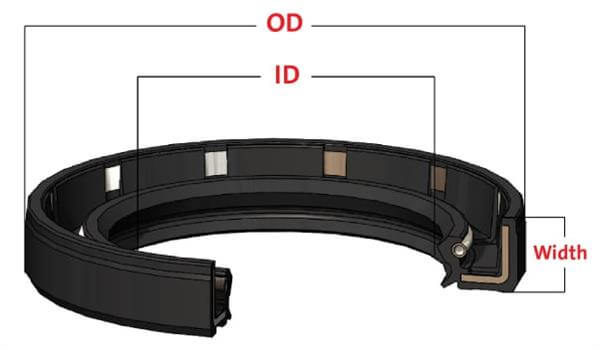

An oil seal has three sizes, ID (inside diameter), OD (outside diameter), W (width). Normally, a standard oil seal size will be given, ID 20 x OD 30 x W 7 mm. Some customers and users who are not professional also call the width H/T (height/thickness).

Metric oil seals are more straightforward because the size is already stamped on the seal. For example, 20 30 7 means that the inside of the oil seal is 20mm, the outside is 30mm and the width is 7mm.

Oil Seal Hardness

The hardness unit of the o-ring is Shore A, which can be easily measured by a Shore A scale durometer. Generally, the hardness of the oil seal is defined by the rubber materials themselves. We normally make NBR oil seals for Shore A 70 and Viton oil seals for Shore A 75.

Oil Seal Colors

We can manufacture oil seals in various colors for customers and customers need to provide the standard Pantone color number. However, considering cost and easy identification, it is generally recommended to choose classific material color oil seals, like black NBR oil seals, brown Viton oil seals, green PU oil seals. If you order a special color that is not commonly used, it may increase the cost and require a larger MOQ with a longer delivery time.