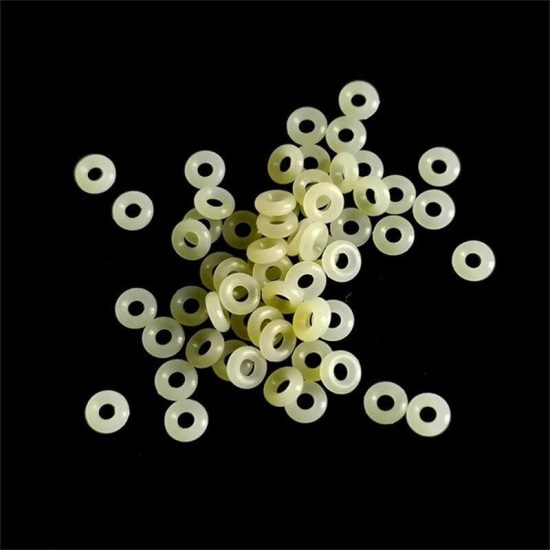

To be one of the best PU / TPU / polyurethane o-rings manufacturers in China

- Payment Way: T/T, Western Union, Paypal

- Incoterm: EXW, FOB, CIF

- Shipping Way: By Air or Sea

- Manufacturer Place: Ningbo, China

- Delivery Time: 7 - 30 days

- Factory Status: Stocked for Sale

Share to SNS:

Description

Polyurethane o-rings are, also known as Urethane o-rings or PU o-rings, made of polyurethane rubber with an extremely low compression set.

Polyurethane is a class of polymers containing urethane repeating unit chain links in the main chain structure. Its tensile modulus is between plastic and rubber, so it is neither plastic nor rubber. According to the processing technology, it can be divided into mixing type polyurethane (MPU), cast type polyurethane (CPU), and thermoplastic polyurethane (TPU), and according to multiple types, it can be divided into polyester type (AU) and polyether type (EU). Its mechanical strength is three to four times that of PVC, and wear resistance is five to ten times that of NR, and oil resistance is one to five times that of NBR. In addition, it also has many outstanding comprehensive physical and chemical properties, such as radiation resistance, ozone resistance, Good dielectric properties, strong elasticity, and high elongation. From the comparison of physical properties, AU is the best low-hardness material. In addition, AU has better oil resistance, heat resistance, and adhesion to metals, while EU has better hydrolysis resistance, cold resistance, and antibacterial performance.

Polyurethane o-rings are more resistant to extrusion than standard o-rings. They are more suitable for environments with high impulse impact forces and space constraints that prevent the use of retaining rings.

Due to the high wear resistance of polyurethane o-rings, polyurethane o-rings are also suitable for dynamic sealing occasions, and the effect is not bad, such as the pilot valve seal of the air valve or the dynamic seal valve core of the main valve. They can also be used for positioning short-stroke clamping cylinders or valve body sealing with HFA hydraulic fluids but lacking lubrication.

Savvy manufactures urethane o-rings in 70 and 90 durometers. We can also produce any type of thermoplastic urethane (TPU) o-rings.

Specifications

- Material: PU / polyurethane / Urethane / AU / EU / TPU

- Temperature Range / Rating: -40 °C (-40 °F) to 90°C (194 °F)

- Low Operating Temperature Limit: -40 °C (-40 °F)

- Maximum Operating Temperature Limit: 90°C (194 °F)

- Durometer Hardness Range: Shore A 40-90

- Standard Durometer Hardness: Shore A 70

- Less Used Duro Hardness: Shore A 50, 90

- Color: Translucent (standard), blue is available

- Outline: Round, square, rectangular, custom

- Cross Section Shape: Round

- Cross Section Width (CS): 0.5 to 20 mm (0.020 to 0.787 inch)

- Inside Diameter (ID): 0.7 to 2965 mm (0.028 to 116.732 inch)

- Standard Size: AS 568, BS 1806, ISO 3601, DIN 3771, JIS B 2401

- Shelf Life: About one year

- Price Level: Normal

Features

Polyurethane o-rings perform high strength, excellent wear resistance, good oil resistance, and solvent resistance, especially for lubricating oil and fuel oil. PU o-rings have good swelling resistance, and good ozone resistance, but not high-temperature resistance.

Chemical Resistance Properties

Excellent

- Ozone

- Chemical

- Oils

- Abrasion

- Tensile Strength

Good

- Weather

Fair

- Flame

Poor

- Watertight

- Deformation

- Acids

- Bases

- Steam

Applications

PU o-rings are used to manufacture reciprocating seals and seals in a variety of wear and high strength applications. Polyurethane o-rings are commonly used in auto parts, marine equipment, aviation equipment, mining machinery, transportation, machinery, and other industrial fields.