We can make new molds to manufacture your square cut o-rings in high quality very fast.

- Payment Way: T/T, Western Union, Paypal

- Incoterm: EXW, FOB, CIF

- Shipping Way: By Air or Sea

- Manufacturer Place: Ningbo, China

- Delivery Time: 7 - 30 days

- Factory Status: Stocked for Sale

Share to SNS:

Description

Square O-Rings are rubber seals with a square-shaped cross-section or profile. Their structure is as simple as common round o-rings, but their sealing effect is higher. They can be cut from elastic tubing with precise dimensions, and can also be molded.

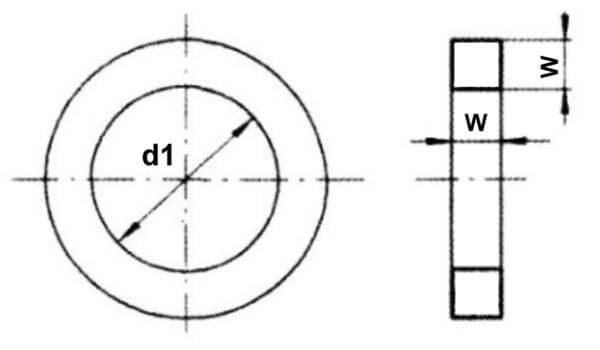

The dimension specifications of square edge o-rings are the inner diameter d1 and the cross-section W. They can obtain a more uniform pressure distribution, so in the same groove size, the cross-section W of the square rings can be reduced compared with o-rings (as shown in the figure). Their compression set ratio can be reduced to 8%~14%, while the ratio of round o-rings is 12~30%.

The cross-section of square o-rings is shown in the following table.

| AS568 Dash Number | Round O-Rings d2 | Square O-Rings W |

|---|---|---|

| 006 – 050 | 1.80 (1.78) | (1.68) |

| 102 – 178 | 2.65 (2.62) | (2.51) |

| 201 – 284 | 3.55 (3.53) | (3.40) |

| 309 – 395 | 5.30 (5.33) | (5.16) |

| 425 – 475 | 6.99 (7.00) | (6.73) |

Working Mechanism

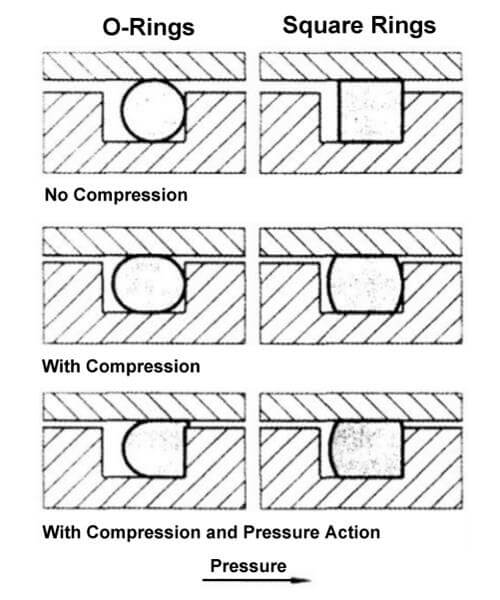

Same as common o-rings, square o-rings are stationary seals that can be used for bidirectional sealing. The initial sealing performance is produced in the radial and axial directions by the pre-contact pressure applied during installation. This contact pressure is correspondingly enhanced by the hydraulic system pressure. This produces a total sealing pressure that increases with the hydraulic system pressure.

Due to the use of good elastic materials, their performance under pressure is similar to that of liquids with high surface tension, so the pressure can be uniformly transmitted to all sides. The cross-sectional area of square o-rings and their cross-sectional characteristics have a high filling degree in the groove, so the reciprocating movement of the sealing ring can be reduced when the pressure changes. This shows that they have the characteristics of high reliability, good sealing, and long service life.

Materials

Square O-Rings are available in a variety of rubber and plastic materials such as NBR, HNBR, Viton, Silicone, EPDM, Teflon, etc.

- NBR Square O-Rings – most cost-effective, used for most industries and applications.

- Viton Square O-Rings – higher temperature, strong chemical resistance, good performance, and higher cost.

- Silicone Square O-Rings – tasteless and non-toxic, used in medical and food industries, especially FDA silicone.

- EPDM Square O-Rings – good resistance to aging, weather, and chemical corrosion, especially used in the automobile industry.

- Teflon Square O-Rings – belongs to plastic material, with high hardness, and good chemical stability, commonly used as a backup ring.

Advantages of Square O-Ring vs Round

- Slower Aging

Rubber and some materials, under the state of compression, that is, under the state of internal stress, will gradually age naturally and reduce their elasticity. Therefore, the sealing ring has a certain service life and is closely related to the quality of the material. Due to the small amount of pre-compression after installation, the aging speed of the squareo-ring is relatively slow. - Good Stability

Due to the shape characteristics of the square o-ring, it will not be twisted after installation; the deformation after pre-compression is small; when the hydraulic pressure changes, the shape change is also small, so it is collectively referred to as the good section stability of the sealing ring. - Good Sealing

When a round o-ring is used as an end face seal, a “suck-back effect” occurs when there is a large pressure pulse. This effect is caused by the pressure between the low-pressure side of the round o-ring and the side of the groove in the groove. When a pressure shock occurs, the liquid is expelled with the movement of the round o-ring. When the pressure drops, a slight leak occurs in a “sweaty” state. There are no sweaty problems when using a square o-ring seal due to its own geometrical features.

In terms of pressure performance, the rated pressure of the o-ring is 32MPa, while the rated pressure of the rubber square ring seal is 50MPa. - Strong Anti-Extrusion Performance

When using round o-rings, under frequent or long-term pressure shocks, a small amount of sealing material will be sheared and squeezed out of the low-pressure side gap over time. This phenomenon is called “extrusion damage”. Under the same conditions, if a square o-ring seal is used, there will be no “extrusion damage”. - High Sealing Pressure

The working pressure of the round o-ring is 32MPa, and the working pressure of the square o-ring is 50MPa. When the round o-ring is used for radial sealing and the pressure exceeds 10MPa, it is necessary to add a backup ring on the low-pressure side to prevent extrusion damage. When using a square o-ring, there is no need to set a backup ring. - Interchangeable

In the original groove of the round o-ring, a square o-ring of the corresponding specification can be installed, so it has good interchangeability with the round o-ring.

Applications

Square o-rings can only be used for fixed sealing applications. Their application and maintenance are basically similar to those of the common o-rings.

They have a small change in shape after installation, and their deformation is not too large even under high pressure. High dimensional stability guarantees good extrusion resistance for sealing gaps.

For some hydraulic valves, it is a very good choice to use rubber square o-rings at each oil port on the bottom plane.

In the coaxial combined sealing rings, square rings are used as elastomers, and they also act as fixed seals.

In the past, only the American square o-ring standard AS568A has been issued, and the German, France, UK, and international square o-ring standards have not been released so far. However, the Simrit company of Freudenberg probably has its own standard.

Square o-rings are a kind of fixed seals with good sealing performance and high reliability, and they are worth popularizing and using.