EPM rubber (full for Ethylene Propylene Monomer) and EPDM rubber (full for Ethylene Propylene Diene Monomer) belong to the ethylene-propylene rubber family. Ethylene propylene rubber (EPR) is a copolymer synthesized from ethylene and propylene monomers. The weight average molecular weight of ethylene-propylene rubber is 200,000 to 400,000, the number average molecular weight is 50,000 to 150,000, and the viscosity average molecular weight is 100,000 to 300,000. The weight average molecular weight is closely related to the Mooney viscosity. The Mooney viscosity value of ethylene-propylene rubber [ML(1+4)100℃] is 25~90, and there are also many varieties with high Mooney viscosity values (105~110). Ethylene propylene rubber can be regarded as the introduction of propylene monomer on the basis of polyethylene [the introduction amount is generally 25%~50% (molar fraction)], thereby destroying the crystallinity of the original polyethylene and making it have rubber properties.

Table of Contents

Types of EPR / EPDM Rubber

Ethylene-propylene rubber is a random copolymer elastomer obtained by solution polymerization or suspension polymerization of ethylene, propylene or ethylene, propylene, and a small amount of non-conjugated dienes as monomers.

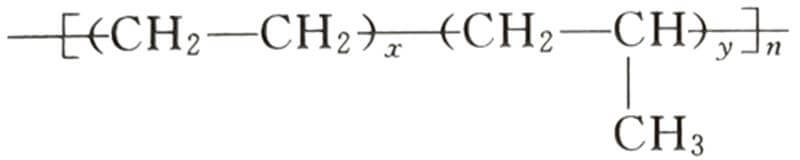

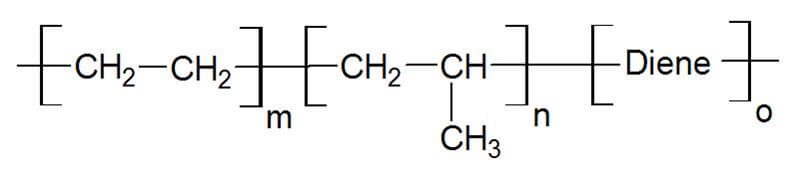

Ethylene-propylene rubber includes two types of Ethylene Propylene Monomer rubber (EPM) and Ethylene Propylene Diene Monomer rubber (EPDM). In addition, there is modified ethylene-propylene rubber and thermoplastic ethylene-propylene rubber. The molecular chain of ethylene propylene diene rubber does not contain double bonds, so it cannot be vulcanized with sulfur, but must be vulcanized with peroxide. EPM is a non-polar, saturated, amorphous rubber. And EPDM rubber is to introduce a non-conjugated diene substance as the third monomer during the copolymerization of ethylene and propylene so that the side group containing double bonds can be introduced into the main chain so that it can be used Traditional sulfur vulcanization method. EPDM is a non-polar, low unsaturation, non-crystalline rubber. According to the different types of the third monomer, EPDM rubber is divided into E-type (ENB-EP-DM), D-type (DCPD-EPDM), and H-type (HD-EPDM). In addition, each category of ethylene-propylene-diene-propylene rubber and ethylene-propylene-diene propylene rubber is classified according to the content of propylene (divided into high, medium, and low grades), Mooney viscosity (divided into high, medium, and low grades), and the third grade. The amount of three monomers introduced (divided into four grades of the low, medium, high, and very high) and whether it is oil-filled or not are divided into several grades.

The introduction amount of the third monomer of EPDM rubber is usually expressed by the iodine value. Different grades of EPDM rubber generally have an iodine value between 6 and 30. Generally, as the iodine value increases, the vulcanization rate increases, the mechanical strength of the vulcanizate increases, and the heat resistance decrease slightly. EPDM rubber with an iodine value of 6~10 has a slow vulcanization rate and can be used in combination with butyl rubber. EPDM rubber with an iodine value of 25-30 is an ultra-fast vulcanization type and can be used in combination with highly unsaturated diene rubbers in any proportion.

Properties of EPDM Rubber

- Ethylene propylene rubber is translucent, colorless to milky white solid, odorless to slightly paraffinic. The relative density (pure product) is 0.855~0.865, the refractive index is 1.476~1.481, the glass transition temperature is -59~-52℃, the embrittlement temperature is -94~-70℃, the specific heat capacity is 2.18kJ/(kg·K), and the solubility parameter ( 25°C) 16.7 (kJ/L)1/2. EPDM rubber is translucent, colorless to milky white to light amber solid, odorless to slightly paraffinic. Relative density (pure) 0.860~0.870, refractive index (material) 1.4771~1.4888, glass transition temperature -60~-50℃, embrittlement temperature -77~-69℃, specific heat capacity 2.09~2.64kJ/(kg·K) , the solubility parameter is 16.2(kJ/L)1/2. Iodine value: ENB type 5~30g I2/100g; DCPD type 5~20g I2/100g; 1,4-HD type 10~20g I2/100g. Ethylene-propylene rubber is soluble in petroleum ether, n-hexane, cyclohexane, n-heptane, benzene, and toluene.

- The performance of ethylene-propylene rubber is directly affected by the composition ratio of ethylene and propylene. The general rule is that with the increase of ethylene content, the mechanical strength of raw rubber and vulcanizate increases, the filling amount of softener and filler increases, the plasticity of the rubber compound is high, the extrusion performance is good, and the stiffness and shape retention of the semi-finished product is good. However, when the ethylene content exceeds 70% (molar fraction), the cold resistance decreases due to the crystallization of the ethylene segment. Therefore, it is generally believed that when the ethylene content is about 60% (molar fraction), the processing properties of ethylene-propylene rubber and the physical and mechanical properties of vulcanizate are better.

- With proper coordination, EPM and EPDM can meet many different needs. The hardness of the article can vary from 25 (Shore A) to 50 (Shore D). Strength properties (tensile strength, tear strength) are directly related to molecular weight. High molecular weight and high ethylene grades have the highest strength properties (and also increase the hardness of the vulcanizate).

- The best compression set properties can be obtained by using high molecular weight green rubber. Higher ENB content is more beneficial. EPDM is generally amorphous and therefore has good low-temperature elasticity. It should be noted that the low-temperature elasticity depends on the ethylene segment structure, length, and ENB content. The low-temperature elasticity improves with increasing molecular weight and weakens with increasing ENB and ethylene content. Tg value of 40 ~ -6o ℃.

- If the temperature does not exceed 135°C, a sulfur/accelerator system should be used in most cases. Above 135°C, a peroxide vulcanization system should be used. In heat-resistant vulcanizates, if a sulfur/accelerator system is used, low sulfur or sulfur/sulfur donor system should be used. For best heat resistance, low molecular weight (so that no oil or little filling), high ethylene content, and ENB content of 2% to 3% can be used. Metal oxides such as zinc oxide and magnesium oxide can improve heat resistance. The dosage of antioxidant RD is usually 1.5 to 2 parts. Other amine and phenolic antioxidants, which usually react with free radicals decomposed by peroxides, should be avoided.

- There are no unsaturated bonds on the main chain of EPM and EPDM, so they have good anti-ozone properties and do not need to add anti-ozonants. The non-polar and inert molecular structure makes EP(D)M resistant to a variety of polar media or molecular oxygen-containing solvents such as ethanol, acetone, esters, glycols, water, especially refrigerants, and brake fluids. Ethylene-propylene rubber has the ability to resist acid and alkali. EP(D)M has poor resistance to hydrocarbons and fuels. Use high molecular weight oil-extended grades of raw rubber to obtain vulcanizates with moderate oil resistance. Increased tertiary monomer content imparts higher crosslink density with consequent improvements in oil resistance. The rubber content as low as possible is beneficial to improve the oil resistance. EPDM can be compounded into a rubber compound with good resistance to animal and vegetable oils, phosphate esters, and silicate esters.

Advantages and disadvantages of EPDM Rubber

- Excellent aging resistance, the best among existing general-purpose rubbers.

- The ozone resistance of ethylene-propylene rubber is particularly good. When the ozone concentration is 100×10-8, the ethylene-propylene rubber will not crack after 2430h, while the butyl rubber will have a large crack after 534h and neoprene after 46h. In terms of ozone resistance, DCPD-EPDM is the best.

- The weather resistance of ethylene-propylene rubber is also very good, and it can be used in the natural environment of sunshine, humidity, and cold for a long time. The ethylene-propylene rubber vulcanizate containing carbon black did not crack after being exposed to sunlight for 3 years, and the physical and mechanical properties changed very little. In terms of weather resistance, EPM is better than DCPD-EPDM and even better than ENB-EPDM.

- Ethylene-propylene rubber has excellent heat resistance. It can generally be used for a long time at 150 °C and can withstand a high temperature of 200 °C when used intermittently. In terms of heat resistance, ENB-EPDM is superior to DCPD-EPDM.

- Insulation performance and corona resistance are better than butyl rubber. And because of low water absorption, the anti-electric performance after immersion is also very good.

- Good resistance to various polar chemicals and acids and bases (except concentrated and strong acids), and the performance changes little after long-term contact.

- It has good elasticity and compression deformation resistance, which is close to the elasticity of natural rubber and good cold resistance. In particular, it is amorphous, which has good elasticity retention at low temperatures. It becomes hard when frozen to -57°C, and becomes brittle at -77°C.

- The strength of pure glue is low, and it must be reinforced to have use-value.

Process Performance of EPDM Rubber

- Easy to accommodate reinforcing agents and softeners, high filling and coordination, and lower product cost due to low density.

- Slow vulcanization rate, 3~4 times slower than general synthetic rubber. Among the three types of EPDM rubber, the D type is cheaper. When vulcanized with sulfur, the E-type vulcanization rate is fast, the vulcanization efficiency is high, and the D-type vulcanization rate is slow. When using peroxide vulcanization, the D-type vulcanization rate is the fastest, followed by E-type.

- Can not be used together with unsaturated rubber, the co-vulcanization performance is poor.

- The self-adhesion and mutual adhesion are very poor, which brings difficulties to the processing technology.

Application of EPDM Rubber

According to the performance characteristics of ethylene-propylene rubber, it is mainly used in several fields requiring aging resistance, water resistance, corrosion resistance, and electrical insulation, such as heat-resistant conveyor belts, cables, wires, anti-corrosion linings, sealing gaskets, door, and window sealing strips, household appliances accessories, etc. It is also very suitable for dock buffers, bridge shock absorption pads, various construction waterproof materials, road pillow pads, various rubber sheets, protective covers, etc. It is also a good material for making wire and cable sheath glue, especially suitable for making high-voltage and medium-voltage cable insulation. It can also manufacture various auto parts such as gaskets, glass seals, radiator hoses, etc. Because of its high dynamic performance and good temperature resistance, weather resistance, corrosion resistance and wear resistance, it can also be used in the manufacture of tire sidewalls, water tires, etc., but the problem of adhesion needs to be solved.