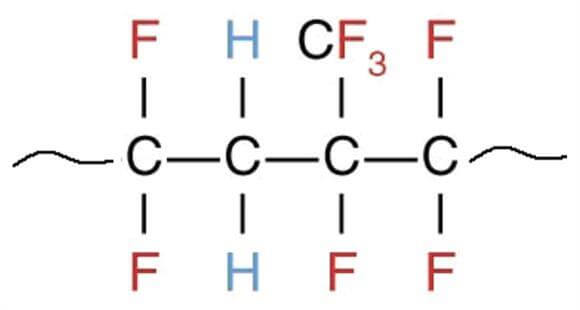

Viton rubber, also known as FKM rubber or FPM Rubber, refers to a synthetic polymer elastomer containing fluorine atoms on the carbon atoms of the main chain or side chain. The introduction of fluorine atoms gives rubber excellent heat resistance, oxidation resistance, oil resistance, corrosion resistance, and atmospheric aging resistance. The earliest ones that were put into industrial production were Viton A and Kel-F elastomers from DuPont and 3M in the United States.

Table of Contents

Types of Viton Rubber

The varieties and grades of fluororubber are specified in accordance with international standards: FPM (FKM or Viton) stands for general fluoro rubber, FPNM stands for fluorinated phosphazene rubber, and AMFU stands for carboxynitroso fluoro rubber. The numbers 2, 3, 4, and 6 after FPM represent vinylidene fluoride, chlorotrifluoroethylene, tetrafluoroethylene, and hexafluoropropylene, respectively. For example, FPM2301 represents fluoro rubber copolymerized by vinylidene fluoride and chlorotrifluoroethylene, and the last digit represents the viscosity. FPM4000 represents tetrafluoroethylene and propylene copolymer fluoro rubber.

Properties of Viton Rubber

- General physical and mechanical properties Fluorine rubber generally has high tensile strength and hardness, but poor elasticity. The friction coefficient (0.80) of type 26 FKM rubber is smaller than that of nitrile rubber (0.90~1.05). In general, the wear resistance is good, but the wear resistance on smooth metal surfaces is poor.

- Heat resistance and temperature resistance In terms of aging resistance, fluorine rubber is comparable to silicone rubber and better than other rubbers. Type 26 Viton rubber can work for a long time at 250°C and short-term work at 300°C. Type 23 FKM rubber still has high strength after aging at 200°C x 1000h, and can also withstand the effect of short-term high temperature at 250°C. Tetrapropylene fluorine rubber can work for a long time at 230℃.

- Corrosion resistance One of the characteristics of FPM rubber is its excellent corrosion resistance. Generally speaking, its stability to organic liquids (fuel oil, solvent, hydraulic medium, etc.), concentrated acid (nitric acid, sulfuric acid, hydrochloric acid), high concentration of hydrogen peroxide, and other strong oxidants is superior to other various rubber. Type 23 fluorine rubber has better resistance to strong oxidizing acids (fuming nitric acid and fuming sulfuric acid, etc.) than type 26 fluorine rubber, but it is resistant to aromatic solvents, chlorinated organic solvents, fuel oil, hydraulic oil, and lubricating oil (especially Is diester, silicate) and boiling water performance is poorer than 26 type.

- Cold resistance Type 26 Viton rubber has poor cold resistance, and it can maintain the limit temperature of rubber elasticity at -15~-20℃. The brittle temperature of 26 the type is -25~-30℃, the brittle temperature of 246 the type is -30~-40℃, and the brittle temperature of 23 the type is -45~-60℃.

- Breathability The air permeability of FPM rubber is lower than that of rubber, similar to butyl rubber and nitrile rubber. The air permeability of FPM rubber increases with increasing temperature.

- Weather resistance and ozone resistance Fluorine rubber is very stable to sunlight, ozone and weather. For example, its vulcanizate can maintain good performance after 10 years of natural aging. The effect of FKM rubber on microorganisms is also stable.

- Radiation resistance Fluoroelastomer is a material that is resistant to moderate doses of radiation. The radiation effect of high-energy rays can cause cracking and structuring of FKM rubber.

- Fire resistance The flame resistance of rubber depends on the halogen content in the molecular structure. The more halogen content, the better the flame resistance. The Viton rubber can burn in contact with the flame, but it will automatically extinguish when it leaves the flame, so the Viton rubber is a self-extinguishing rubber.

- Electrical properties The electrical insulation performance of 26-type FKM rubber is not very good, and it is only suitable for low-frequency and low-voltage applications.

- High vacuum resistance Fluoroelastomer has excellent vacuum resistance. This is because fluorine rubber has a small outgassing rate and a very small amount of gas volatilization under high temperature and high vacuum conditions. Type 26 and Type 246 Viton rubber can be used in ultra-high vacuum applications ranging from 133×10-9 to 133×10-10 Pa, and are important rubber materials in spacecraft.

More Information about Viton Rubber

The tensile strength of the fluoroelastomers is still substantially satisfactory. Compression set resistance is an important indicator for fluoroelastomers.

The result of the chemical attack is volume swelling of the elastomer (generally considered a reversible process). Swelling within 10% can be considered beneficial to improve the sealing force of the elastic gasket, but too high swelling will lead to permanent sealing failure. Chemical attacks can also cause material degradation, which must be avoided.

Compared with ordinary Viton rubber, peroxide-cured Viton rubber has higher performance, and the application range has been further expanded. In addition, it has the characteristics of high tensile strength and short scorch time. The swelling resistance of peroxide-cured fluoroelastomers and the resistance to thermal water degradation have been greatly improved.

In harsh media, the volume swelling properties of Viton of different vulcanization systems are also different. Bisphenol vulcanization systems swell more in glacial acetic acid/water and swell minimally in vinyl amine. In high temperature and high-pressure water vapor, the volume swelling of peroxide curing systems is minimal. In this way, the most suitable vulcanization system can be selected according to actual needs. All FKM’s swell in chlorocarbon or fluorocarbon solvents. Even at 210°C, fluoroelastomers still maintain good working ability in most solvents. In order to overcome the shortcomings of the improvement of medium resistance with the increase of fluorine content, but the decrease of processing performance and pressure change performance, the newly developed ternary fluoroelastomer has the characteristics of good processing performance, low-pressure change, and high fluorine content. Other properties such as heat resistance, oil resistance, and tensile strength are not lost.

Application of Viton Rubber

Because Viton rubber has the characteristics of high-temperature resistance, oil resistance, high vacuum resistance, acid and alkali resistance, and resistance to various chemicals, it is widely used in cutting-edge technologies such as modern aviation, missiles, rockets, astronautics, ships, atomic energy, automobiles, shipbuilding, chemical, petroleum, telecommunications, instrumentation, machinery, and other industrial sectors have been applied.

Fluorine rubber can be used in combination with nitrile rubber, acrylate rubber, ethylene-propylene rubber, silicone rubber, fluorosilicone rubber, etc. to reduce costs and improve physical and mechanical properties and process performance.

Read more knowledge about FKM rubber.