Savvy manufactures food grade FDA o-rings for many years in China.

- Payment Way: T/T, Western Union, Paypal

- Incoterm: EXW, FOB, CIF

- Shipping Way: By Air or Sea

- Manufacturer Place: Ningbo, China

- Delivery Time: 7 - 30 days

- Factory Status: Stocked for Sale

Share to SNS:

Description

Food grade FDA o-rings are specialized sealing rings or gaskets designed for use in the food and beverage industry. These o-rings are made from materials that are safe for contact with food and drink, ensuring that they do not contaminate the products they come into contact with. FDA-approved o-rings are crucial in maintaining the integrity of various equipment and components used in food processing, packaging, and handling.

Features of Food Grade FDA O-Rings

- Material Safety: Food-grade o-rings are typically made from materials approved by regulatory agencies like the U.S. Food and Drug Administration (FDA) for use in food and beverage applications. Common materials include silicone, EPDM (Ethylene Propylene Diene Monomer), and certain types of fluorocarbons.

- Non-Toxicity: FDA o-rings are formulated to be non-toxic, meaning they will not leach harmful chemicals or substances into the food or beverages they come into contact with.

- Resistance to Food and Beverage Components: Food-grade o-rings are engineered to resist exposure to various food and beverage ingredients, including acids, bases, oils, and moisture. They maintain their integrity even when subjected to these substances over time.

- Temperature and Chemical Resistance: They can withstand various temperatures, ensuring they remain effective in hot and cold food processing environments. Additionally, they are often resistant to cleaning chemicals and sanitizers used in food industry equipment.

- Hygienic Design: FDA o-rings have minimal crevices and easy-to-clean surfaces to prevent bacterial growth and facilitate thorough cleaning and sanitization.

- Compliance: Manufacturers of FDA o-rings adhere to strict quality and safety standards to ensure FDA compliance with food contact materials regulations.

- Test: The U.S. Food and Drug Administration will not issue a certificate directly, but some international test groups, such as SGS, TUV, and Intertek, can test these o-rings in their labs. The test is rigorous, and they often use some test food to test these o-rings for a long time to ensure they can meet FDA standards.

Types of Food Grade FDA O-Rings

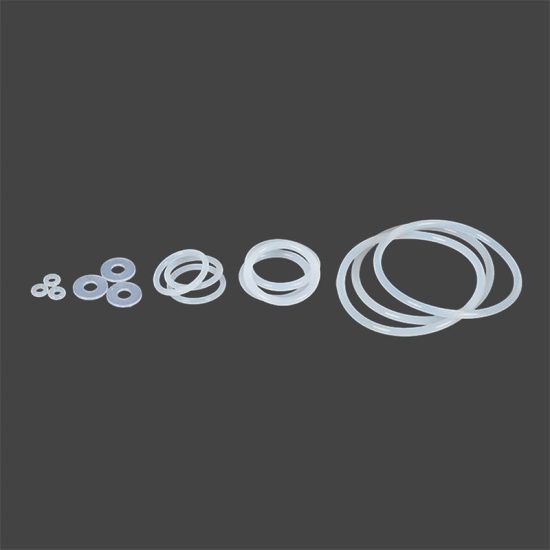

(1) Food Grade FDA Silicone O-Rings – Generally, food-grade FDA o-rings are produced with silicone rubber, mainly gas-phased silicone.

(2) Food Grade FDA EPDM O-Rings – These o-rings are seldom used in applications, but sometimes, customers need them.

(3) Food Grade FDA NBR O-Rings – Are nitrile o-rings food safe? No, common NBR o-rings are not food-safe. Only FDA-approved Buna-N rubber material can be used to make food-grade NBR o-rings.

(4) Food Grade FDA Viton O-Rings – Because of the high performance of FKM rubber, FDA-approved Viton o-rings have an increasing trend in practical applications.

Food Grade Silicone O-Rings

Food-grade silicone o-rings are non-toxic, odorless, and have stable chemical properties. Under normal conditions, they do not react with acid, alkali, or salt except caustic alkali and hydrofluoric acid. They can resistant high temperatures of 220°C and be used in a microwave oven without any toxic or side effects on the human body. Compared with other material parts, they are safer and healthier. For example, common plastics must add many antioxidants, plasticizers, stabilizers, etc., during production. These additives are harmful to the human body. Food-grade silicone o-rings have strong stability properties and are more in line with the requirements of a healthy and safe life. Food-grade silicone rubber is already found in ordinary people’s homes. The most common one is the gasket used for sealing in pressure cookers. It is easy to clean, non-toxic, and harmless.

We welcome you to refer to our silicone o-ring page: https://savvyrubber.com/vmq-silicone-o-rings/.

Applications

Food-grade o-rings are commonly used in various food processing equipment, including pumps, valves, fittings, and seals, as well as in beverage dispensing systems, commercial kitchen appliances, and pharmaceutical applications. Their primary purpose is to create a reliable seal that prevents contamination and leakage, helping maintain the quality and safety of food and beverage products throughout production and distribution.