We manufacture high-quality X-Rings and Quad Ring Seals for many years.

X-Ring, also known as quad ring seal, is a four-lip seal with a shape similar to X, so it is called X-Ring. Its performance has been improved on the basis of the o-ring and can replace most o-ring occasions. In the rubber seal industry, X-Ring is usually classified as O-Ring, and many people call it x profile o-ring or x-ring face seal.

Overview

With the development of modern industrial sealing technology, the defects of o-rings in sealing technology are more and more manifested. For example, the o-ring is prone to helical twist damage during the sealing installation and the use of the dynamic seals; when the pressure is high, it is prone to extrusion, causing gap bites; in the dynamic sealing state, because of high start frictional resistance it increases the power loss of moving parts; due to the poor self-lubricating effect and the anti-distortion ability during use is low, it is also easy to cause distortion damage. These defects and deficiencies can easily lead to seal failure. Due to its special geometric shape, the X-Ring or Quad Ring seal has many advantages that the o-ring does not have in its sealing function, especially in the dynamic seal.

How it functions

The quad ring seal is a double-acting seal with its elastic sealing ability. The radial or axial contact stress generated by the pre-compression during initial installation is superimposed with the system pressure to achieve the sealing function.

The superimposed sealing force increases as the system pressure increases. Under the action of pressure, the quad ring seal can transfer the pressure evenly to all sides like a fluid with high surface tension.

Materials

Same as the Rubber O-Ring Seals, the main materials of Quad-Rings are also NBR, Viton, and Silicone. Higher performance materials can be made into high-grade Aflas x-ring seals, FDA EPDM quad o-rings, and so on.

NBR is the first considering material we suggest. About 50% of quad rings in the world are made of NBR compound because of its good property and low cost.

FKM / Viton is an x-ring material with the best comprehensive performance and is widely used in various sealing equipment with high standards. It was first invented by DuPont company and issued under the trade name “Viton”. With the time being, more and more people used to call this material Viton.

Silicone is more and more used in medical and food industries, especially FDA silicone. It is tasteless and non-toxic, not afraid of high temperatures, and resistant to severe cold.

Excepting the above popular rubber materials, other materials are also available in Savvy company.

Measuring Sizes

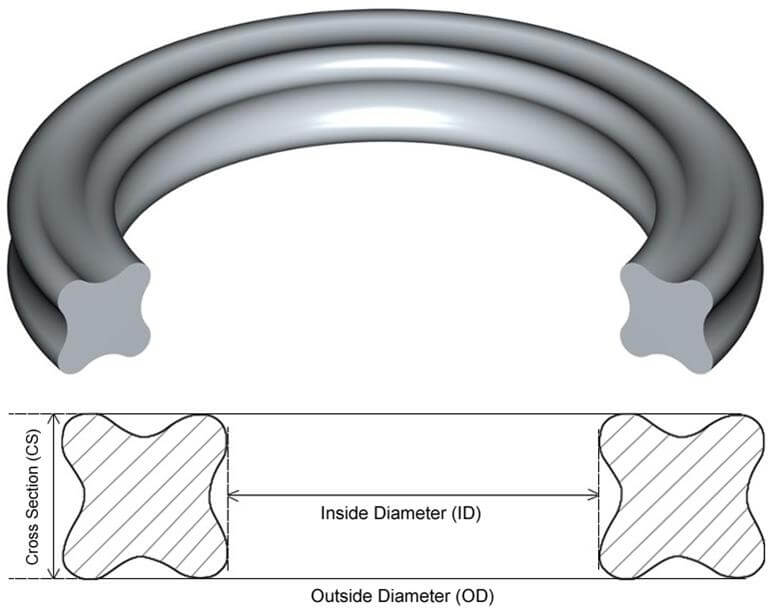

An x-ring has three sizes, ID (inside diameter), OD (outside diameter) and CS / W (cross-section / width). Normally to specify the ID and CS is enough, namely, a standard size will be given like, ID 20 x CS 2 mm.

From the right picture, you can easily know the

Outside Diameter = Inside Diameter + Cross Section * 2

OD = ID + CS*2

Savvy manufactures many standard sizes of the x-rings in our factory. You can check the Standard AS568 X-Ring Size Chart here to find your suitable seals.

Advantages of X-Rings VS O-Rings

- X-Rings have four sealing contact surfaces, in the case of using the same rectangular groove used by o-rings, which are not easy to produce spiral twists whether in static sealing or dynamic sealing state, especially in the use of dynamic sealing, so its reliability is far superior to o-rings.

- Because Quad Rings have 4 evenly distributed concave areas, under the action of large working pressure, the displacement from one side to the other side is small, which can effectively eliminate the extrusion phenomenon and avoid gap bites.

- The concave area of X-Rings stores a certain amount of lubricating oil during use has a high self-lubricating ability and has a much higher resistance to distortion damage than o-rings.

- The compression amount of Quad Rings is small and in the dynamic sealing state, the starting frictional resistance is small. Under the working pressure of 0.7MPa, the frictional resistance is only 1/2 of o-rings.

- Quad Rings are more reliable than О-Rings but are much more expensive to manufacture than O-Rings. At present, X-Rings are only used in some special industries, mainly because mold processing is difficult and the price is high.

X-Rings & O-Rings Difference

In addition to the cross-section shape, the differences between X-Rings and O-Rings are much more in terms of performance and price. Through the above performance comparison, we can know that the place where O-Rings can be used can be replaced by Quad-Rings, and the sealing effect is very good, but the place where Quad-Rings can be used, the O-Rings may not be able to use, it needs to be considered according to the specific technical requirements.

Applications

X-Ring Rubber Seals are widely used but are mainly used for dynamic seals and their use is limited by pressure and speed.

Application of Dynamic Seal

For sealing reciprocating pistons, piston rods, plungers.

Shafts or spindles for sealing oscillating, rotating, or helical movements.

Application of Static Seal

Seals radially stationary parts such as sleeves, end caps, and tubes.

Seals axially stationary parts such as flanges, cover plates, etc.