Savvy is a trustable nylon o-rings manufacturer & supplier in China

- Payment Way: T/T, Western Union, Paypal

- Incoterm: EXW, FOB, CIF

- Shipping Way: By Air or Sea

- Manufacturer Place: Ningbo, China

- Delivery Time: 7 - 30 days

- Factory Status: Stocked for Sale

Share to SNS:

Description

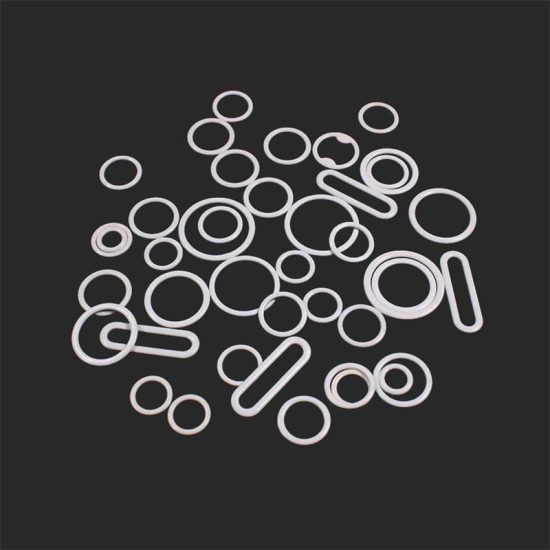

Nylon o-rings are a type of sealing gasket or mechanical seal made from nylon material. Like the PTFE o-rings, nylon o-rings are also plastic seals.

Nylon or Polyamide (short for PA) is a general term for thermoplastic resins containing repeating amide groups – [NHCO] – on the main chain of the molecule, including aliphatic PA, aliphatic-aromatic PA and aromatic PA.

Among them, aliphatic PA has many varieties, large output, and wide application. The specific number of carbon atoms of the synthetic monomer determines its name. There are many varieties of PA, including PA6, PA66, PAll, PA12, PA46, PA610, PA612, PA1010, etc., as well as many new varieties such as semi-aromatic nylon PA6T and special nylon developed in recent years.

Unlike ordinary rubber o-rings, they are not vulcanized but processed by CNC. Savvy produces high-quality nylon o-ring products, ensuring high precision, smooth appearance, and fast delivery. Please get in touch with our sales department, [email protected], to place an order.

Specifications

- Material: Nylon, Polyamide, PA, PA6, PA66, PA1010

- Temperature Range / Rating: -40 °C (-40 °F) to 120°C (248 °F)

- Low Operating Temperature Limit: -40 °C (-40 °F)

- High Operating Temperature Limit: 120 °C (248 °F)

- Durometer Hardness Range: Fixed

- Standard Durometer Hardness: Shore D 80

- Color: Natural (standard), white, blue, black, orange, custom color is available

- Outline: Round, square, rectangular, custom

- Cross Section Shape: Round

- Cross Section Width (CS): 0.5 to 20 mm (0.020 to 0.787 inch)

- Inside Diameter (ID): 0.7 to 2965 mm (0.028 to 116.732 inch)

- Standard Size: AS 568, BS 1806, ISO 3601, DIN 3771, JIS B 2401

- Shelf Life: About 5 years

- Price Level: Normal

Features

Nylon o-rings are wear-resistant, oil-resistant, and corrosion-resistant. They are widely used in automobiles, machinery, electrical, and other industries.

Advantages:

- Wear resistance: nylon o-rings have good wear resistance and can work in high pressure, high temperature, and high wear environments.

- Oil resistance: nylon o-rings have good oil resistance and can work in environments containing oil, fat, and other media.

- Corrosion resistance: nylon o-rings have good corrosion resistance and can work in corrosive environments such as acids, alkalis, and salts.

- Easy to install: The nylon n-rings are easy to install; just put them into the hole that needs to be sealed.

Disadvantages:

- Not resistant to high temperatures: the high-temperature resistance of nylon o-rings is generally below 100°C.

- Not resistant to high pressure: the high-pressure resistance of nylon o-rings is generally below 10MPa.

- Not resistant to aging: when nylon o-rings work in high temperature, high pressure, or corrosive solid media, they will age, and their sealing performance will decrease.

Chemical Resistance Properties

Excellent

- Weather

- Chemical

- Oils

- Abration

- Deformation

- Tensile Strength

Good

- Acids

- Bases

Fair

- Watertight

Poor

- Ozone

- Steam

- Flame

Applications

Automotive industry: nylon o-rings are widely used in automobile lubrication systems, cooling systems, fuel systems, braking systems, etc. Machinery industry: nylon o-rings are widely used in mechanical transmission systems, hydraulic systems, pneumatic systems, etc. Electrical industry: nylon o-rings are widely used in insulation and waterproof electrical equipment systems.